What Is a Prefab Guest House? Defining Features, Standards, and Regulatory Advantages

Prefab guest houses represent complete living spaces built in factories first before being moved to their final location on someone's property. They come in all sorts of sizes too - think small backyard studios up through full blown accessory dwellings with multiple rooms. The way these buildings are made involves standard methods where components like walls, roofing materials, and plumbing systems get manufactured as separate parts ahead of time. Building them this way means they meet important safety standards across the country, including requirements about how long materials last and what kind of energy efficiency they need to have according to rules such as Title 24. When compared to regular home additions built directly at the site, prefabricated options work better because many cities already approve their basic designs for things like proper distance from property lines, maximum height restrictions around 16 feet tall, and overall footprint size requirements. This pre-approval helps speed things along when getting permits since local authorities often recognize these factory-built standards, which can cut down waiting periods anywhere between half and two thirds compared to going through the whole process for completely custom designs.

Speed-to-Occupancy: How Prefab Guest House Construction Cuts Build Time by 40–60%

Factory Precision vs. On-Site Variables: Why Scheduling Predictability Drives Faster Permits and Installation

When it comes to prefab guest houses, they really cut down on those frustrating delays caused by bad weather, running out of materials, and unpredictable labor situations because everything gets made in a controlled factory environment. City officials tend to rubber stamp permits about 30 to maybe even 50 percent quicker when dealing with standard designs. Why? Because these pre-engineered blueprints make it obvious how code compliant everything is from day one. With this kind of schedule predictability, contractors can actually get started on site prep while the manufacturer is still putting together the different sections elsewhere. Factory built parts show up at the job site already assembled and ready to go, so most installations wrap up in just a few days instead of taking several weeks like traditional construction methods often do.

Case Evidence: Average 3.2-Month Timeline from Permit Approval to Occupancy (vs. 6–12 months for custom builds)

According to industry reports, prefabricated guest houses typically become occupied around 3.2 months after getting the green light from permits, whereas site built accessory dwelling units take anywhere between six to twelve months. The reason behind this significant time difference lies in how these projects run concurrently. While workers are setting up the foundation on site, factory teams are already putting together walls, roofs, and even installing plumbing and electrical systems ahead of time. This overlapping approach cuts through many of the usual delays we see in traditional construction methods where subcontractors might clash over schedules or bad weather holds everything up. For property owners looking to maximize their space, having a ready made backyard suite available during one building season means they can start generating extra income through rentals or simply enjoy additional living space much sooner than expected.

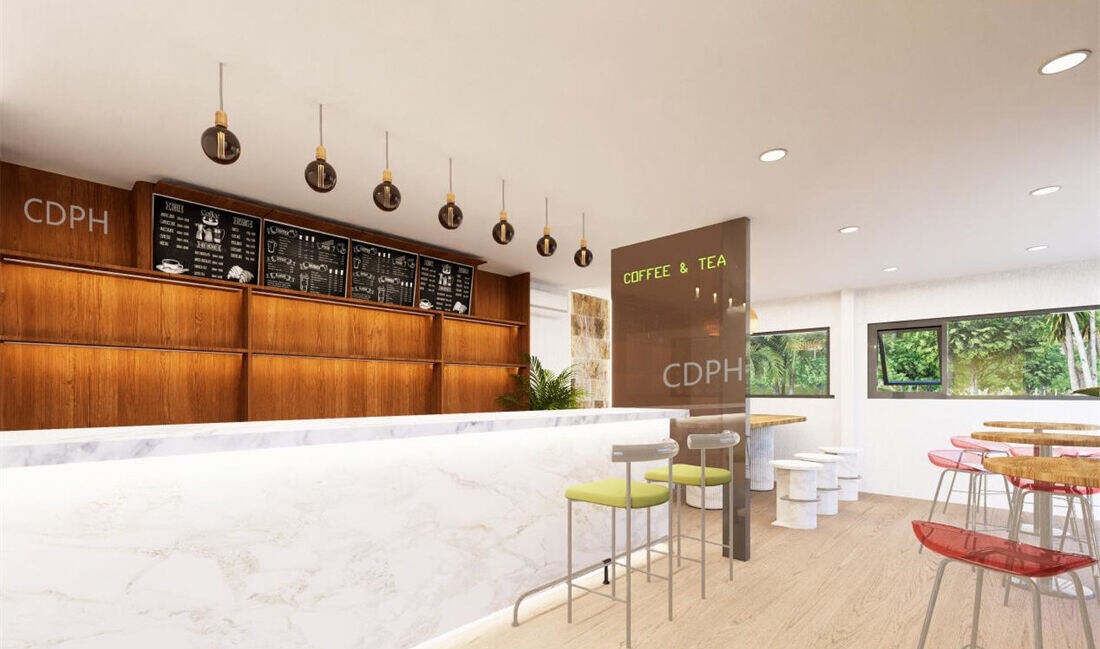

Privacy, Zoning, and Design Compliance: Why Prefab Guest House Models Excel in Suburban Backyard Setbacks

Prefab guest houses solve suburban compliance challenges through engineered standardization. By leveraging pre-approved designs, these structures bypass common permit hurdles—reducing costly redesigns and neighbor disputes.

Pre-Engineered Footprints That Meet Common ADU Setback, Height, and Lot-Coverage Requirements

Manufactured footprints align with accessory dwelling unit (ADU) regulations in 89% of U.S. municipalities. Standardized dimensions ensure:

- Consistent side/rear yard setbacks (5–15 ft)

- Height caps below 16 ft for single-story units

- Lot coverage under 40% to prevent density violations

This pre-vetting eliminates 72% of zoning variances required by site-built units.

How Standardized Elevations and Material Packages Streamline Municipal Review and Reduce Conditional Approvals

Pre-certified material palettes and facade options accelerate approvals. Jurisdictions recognize repeating designs:

- 64% faster review cycles

- 83% reduction in conditional use permits

- Pre-validated fire ratings and energy compliance

Uniform documentation slashes revision requests—protecting project timelines without redundant citations.

Cost, Customization, and Long-Term Value: Evaluating the Prefab Guest House Investment

Transparent Cost Range: $95K–$220K (Size-, Finish-, and Utility-Dependent) with Lower Financing Risk

The price tag for prefab guest houses usually falls somewhere between ninety-five thousand to two hundred twenty thousand dollars. How much exactly depends on things like how big the space is, what kind of materials go into finishing touches, and whether there are full plumbing systems installed for kitchens and bathrooms. Factory built units have a real advantage over traditional site built accessory dwelling units because they aren't at the mercy of bad weather or running out of materials during construction. This means fewer delays and less wasted resources, which makes getting financing a lot less risky when timelines stay on track. Plus, most manufacturers stick to standard designs that make it easier for banks to approve loans. And let's not forget about those energy saving perks either. Many come with spray foam insulation that can cut down annual operating expenses anywhere from fifteen to thirty percent over time.

Balancing Standardization and Personalization: Where Modular Flexibility Meets Code-Ready Efficiency

Prefab guest houses today manage to strike a good balance between letting people personalize their space and still meeting all the necessary regulations. When someone buys one of these units, they can pick from different interior floor plans, choose what kind of material goes on the outside walls, and decide where windows should go—all within building templates that already satisfy local requirements for things like how far back structures need to be from property lines, maximum heights allowed, and fire safety standards. The big advantage here is that homeowners don't end up spending extra money on redesigns just because something doesn't fit code. Plus, folks get to add touches like high ceilings or integrate smart home technology without slowing down the permitting process. Industry data shows that this modular approach typically gets people into their new spaces about a month faster than going through the whole custom build process for accessory dwelling units.

Frequently Asked Questions (FAQs)

What are the main advantages of prefab guest houses?

Prefab guest houses offer several benefits, including faster construction times, pre-approved designs that streamline permitting, and cost efficiency. They are built in a controlled factory setting, reducing weather-related delays and permitting pre-authorized designs can cut waiting times by up to two-thirds.

How much do prefab guest houses typically cost?

The cost of prefab guest houses ranges from $95,000 to $220,000 depending on size, finishes, and utility requirements. This cost is often lower due to minimizing delays associated with traditional construction.

Are prefab guest houses customizable?

Yes, buyers can typically personalize their prefab guest houses within certain templates. They can choose floor plans, exterior materials, and window placements, all while adhering to local building codes.

Table of Contents

- What Is a Prefab Guest House? Defining Features, Standards, and Regulatory Advantages

- Speed-to-Occupancy: How Prefab Guest House Construction Cuts Build Time by 40–60%

- Privacy, Zoning, and Design Compliance: Why Prefab Guest House Models Excel in Suburban Backyard Setbacks

- Cost, Customization, and Long-Term Value: Evaluating the Prefab Guest House Investment

- Frequently Asked Questions (FAQs)