Understanding Container House Costs: Key Factors That Shape Your Budget

Size, Condition, and Container Type: 20ft vs. 40ft, Standard vs. High Cube

The size of containers has a big impact on what people spend and how comfortable they are living inside them. Most folks looking at secondhand options will find that a regular 20 foot container gives about 160 square feet of space for somewhere between $1,500 to $3,500. If someone wants more room, going for a 40 footer doubles the available area to around 320 square feet, yet it only costs roughly $3,000 to $6,000 which is just 30 to 50 percent extra money upfront. Then there's those taller High Cube containers too. These stand at 9.5 feet compared to the normal 8.5 feet height. They usually cost an additional $500 to $1,000 each, but worth every penny when considering better air circulation, more headspace, and all sorts of creative possibilities like adding mezzanine levels or installing proper heating and cooling systems.

- Space efficiency: One 40ft container often accommodates full kitchens and bathrooms more comfortably than two joined 20ft units—reducing labor, sealing, and thermal bridging points.

- Transport constraints: 40ft units require wider access roads and specialized cranes, increasing logistics fees by 15–25%.

- Design flexibility: High Cube models simplify ductwork routing and multi-level planning, lowering long-term mechanical installation costs.

New vs. Used Containers: Balancing Cost, Durability, and Design Potential

Buying used containers can save anywhere from 40 to 60 percent compared to brand new ones, which typically range from $4,000 to $8,000 versus $1,500 to $4,000 for secondhand options. But don't skip the inspection process. Look specifically for CSC certified containers first, then examine the floors closely since corrosion replacement costs between $1,000 and $2,500 if needed. Check all those tricky spots too - rust tends to hide in seams and corners. Also watch out for any old labels indicating previous hazardous materials. Sure, new containers come with guaranteed structural strength and corten steel quality, but most people find the extra expense doesn't really pay off for home conversions, especially after proper retrofitting of good quality used units. The numbers back this up too; industry reports indicate around 80% of successful container house builds start with used containers. And remember to set aside roughly 10 to 15% of your total budget just in case something unexpected pops up during the project.

Container House Floor Plans: Designing Efficient and Scalable Layouts

Single-Container Layouts: Smart Space Utilization for Compact Living

Tiny houses made from single containers (around 160 to 320 square feet) work best when designed with purposeful multifunctionality rather than just cutting corners on space. Things like convertible furniture pieces, clever vertical storage options, and built-ins such as fold down desks or drawers inside stairs can actually boost usable area by about 40 percent. The open concept layout approach removes those unnecessary walls that don't support the structure, letting natural light bounce around better and making the whole place feel bigger than it really is. For the different living zones kitchen area, bedroom spot, and lounging space designers need to create smooth transitions without putting up actual walls. This maintains the container's strength while still giving residents all their necessary private moments throughout the day.

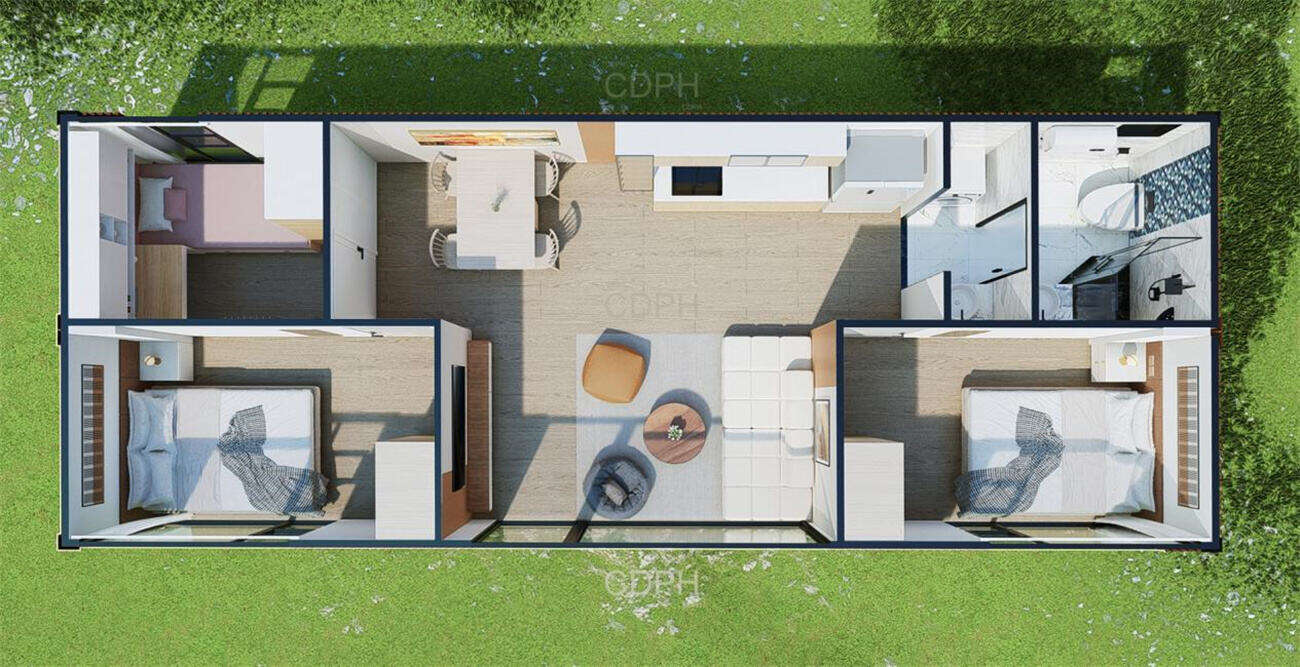

Multi-Container Configurations: L-Shaped, U-Shaped, and Stacked Floor Plans

Multi-unit arrangements unlock scalability and architectural expression:

- L-Shaped Plans: Define private outdoor courtyards while naturally separating public and private zones.

- U-Shaped Designs: Enclose central patios for climate-responsive outdoor living.

- Stacked Arrangements: Double square footage on minimal footprint—ideal for urban infill or sloped sites.

These configurations support complex, open-concept container house designs with dedicated rooms and communal areas. Strategic cuts between containers create expansive interior volumes, while engineered connections ensure load distribution across modified frames. Cantilevered sections extend covered outdoor space, and thermal bridging mitigation at joints preserves energy efficiency in larger builds.

Design and Structural Choices That Impact Cost and Livability

Strategic Placement of Doors, Windows, and Interior Walls

Each time there's an opening made in a container, it weakens the basic structural integrity of the unit and needs extra support to stop things like buckling or bending under stress. When builders cut out areas for doors or windows, they typically see a cost increase somewhere between 5% and maybe even 15%, particularly if these cuts happen at corners or follow main load-bearing lines throughout the structure. The best practice? Try to place all those necessary openings as far away as possible from where the container actually carries weight. For interior spaces inside converted containers, most walls shouldn't carry any structural load themselves. Instead, when creating those modern open-concept living spaces people love so much nowadays, smart steel bracing systems can take over the job that traditional walls would normally do, maintaining safety standards while keeping future maintenance issues at bay.

Insulation, Climate Control, and Long-Term Comfort Considerations

Steel really moves heat and cold around fast, which means good insulation isn't just important—it's absolutely essential for keeping things comfortable long term while controlling those energy bills. When buildings aren't properly insulated, especially in places with harsh weather, HVAC systems have to work way harder, sometimes using 40% more power according to industry data. Spray foam insulation in closed-cell form actually performs better than regular fiberglass batts when it comes to stopping heat transfer and keeping moisture out, even though it does cost about 30% more upfront. The smart money goes on continuous insulation layers particularly at roofs and floors since that's where condensation tends to form and start eating away at metal structures. For container homes specifically, combining top quality insulation with strategically placed windows that allow for natural airflow makes a huge difference. This approach cuts down on reliance for air conditioning and helps these spaces stay functional and efficient for many years to come.

FAQ

What are the main factors affecting container house costs?

The main factors include size, condition, container type, whether the container is new or used, and design and structural choices.

Is it better to use a 20ft or 40ft container for building a container house?

While 20ft containers are more affordable, 40ft containers offer more space efficiency, especially for full kitchens and bathrooms, and often cost less in terms of labor.

Should I buy a new or used container for my house project?

Used containers are more cost-effective, saving between 40% to 60% compared to new containers. However, inspecting them for structural integrity is crucial.

How does insulation impact the long-term comfort of container homes?

Proper insulation is essential for controlling temperature and reducing energy costs. Spray foam insulation is recommended over fiberglass for containers.