Why Container Offices Are the Future of Modular Office Design

Modular Office Construction Benefits vs. Traditional Build-Outs

Container offices are changing how we think about workspaces because they come ready made. Traditional office buildings take anywhere from six to twelve months to construct on site, but container offices get built in factories instead. This means projects finish much faster too around 65% quicker actually and there's no waiting around for bad weather to pass. When these containers arrive at their destination, everything inside works right away electricity, heating systems, even good insulation all installed already. Less stuff gets wasted during construction compared to regular buildings somewhere between thirty and forty percent less according to recent studies. The metal frames inside these containers make them stronger than normal wooden buildings when it comes to earthquakes or severe storms. And here's another big plus nobody can beat the fact that whole offices just pack up and move across country on flatbed trucks whenever business needs change. Permanent buildings just don't offer this kind of flexibility.

Data-Driven ROI: 40–60% Faster Deployment and 25% Lower CapEx in Commercial Container Office Projects

Container offices deliver compelling financial returns. Parallel factory and site workflows shorten project durations by 40–60%, accelerating time-to-revenue. Standardized manufacturing and bulk procurement reduce capital expenditure by an average of 25%. The contrast is clear:

| Cost Factor | Traditional Build | Container Office |

|---|---|---|

| Construction Timeline | 9–12 months | 3–5 months |

| Material Waste | ~30% | 8–10% |

| Foundation/Utility Cost | $220,000 | $95,000 |

These efficiencies scale meaningfully: a 10-unit financial services campus achieved $740,000 in savings and launched five months ahead of schedule (Commercial Real Estate Journal, 2023). Accelerated depreciation schedules further strengthen ROI—most projects reach break-even within 18 months.

Industry Paradox: High Customization Without Sacrificing Speed or Compliance

Container offices have cracked the problem of getting custom designs built quickly. With advanced BIM modeling, we can create all sorts of complicated setups these days multi level stacks, cantilevered parts, even curved walls while still sticking to our standard 12 week build time. A company actually managed to produce 28 different layouts for one big project and still got everything installed on schedule. The good news is code requirements aren't an afterthought anymore. Fire suppression, proper ADA access paths, and insulation way beyond what IECC requires get built right into the containers as they're made. What does this mean? Custom office parks for businesses in tight regulatory fields like hospitals or schools can go up much quicker than the usual cookie cutter commercial buildings that take forever to get approved and constructed.

From Standard Container to Fully Functional Office: The Modular Transformation Process

Shipping Container Office Design: Structural Adaptation and Code Compliance Pathways

When turning old containers into proper office spaces, it takes real engineering skill beyond simple repurposing. Doors and windows need careful placement using plasma cutting equipment so we don't compromise the strength of those corrugated steel walls that actually hold everything together against earthquakes and strong storms. For keeping things comfortable inside, most folks go with either high R-value spray foam or rigid panels between the walls, which meets all those energy efficiency standards from IECC. Before anyone starts putting in desks and chairs, every single change has to check off local building regulations first. That means getting approval for structural reinforcements, making sure all interior surfaces won't catch fire easily, and verifying that emergency exits meet accessibility standards required by law.

Turnkey Container Office Setup: Prefabrication, Site Logistics, and Plug-and-Play Integration

The whole concept of turnkey solutions really depends on doing most of the work away from the actual construction site. Around 90 percent of what goes into building these structures gets done in factories first. We're talking about all the electrical runs, those long plumbing channels, and even the big HVAC ducts. This approach cuts down how long projects take to deliver compared to old school methods, usually saving somewhere between 40 and 60 percent of time. What's left for the site itself? Mainly getting the foundations right. That means setting up proper concrete piers or laying down gravel bases depending on what works best for each location. The utilities also need to connect properly with whatever existing infrastructure is there. When everything arrives at the site, special leveling systems come into play along with components that have already been tested and ready to connect immediately. Most installations become fully operational just a few hours after setup starts. No mess left behind either since there's minimal on site fabrication required. This makes expansion much smoother when multiple units need to be integrated together later on.

Scalability and Portability: Built to Grow and Move with Your Business Needs

Expandable Options and Seamless Integration of Additional Units Across Job Sites

Container offices really do scale well when business needs change. When teams expand or new projects come along, adding standard container modules takes just weeks instead of the months required for traditional buildings, according to Industrial Construction Data from last year. The numbers show these modular setups can expand capacity about 35 to 50 percent faster than regular office construction. At current sites, new containers plug right into existing power systems and share heating/cooling equipment too, so there's hardly any downtime during installation. And what makes them even better is their portability factor. Entire offices can move locations without tearing anything down first, which saves money on both demolition and rebuilding while cutting waste significantly. We've seen one container serve three different project teams across several years, slashing property costs by around 30% in the long run. For companies needing flexible workspace solutions, this combination of quick expansion and easy relocation creates something pretty special in today's market landscape.

Customization That Enhances Functionality and Brand Identity

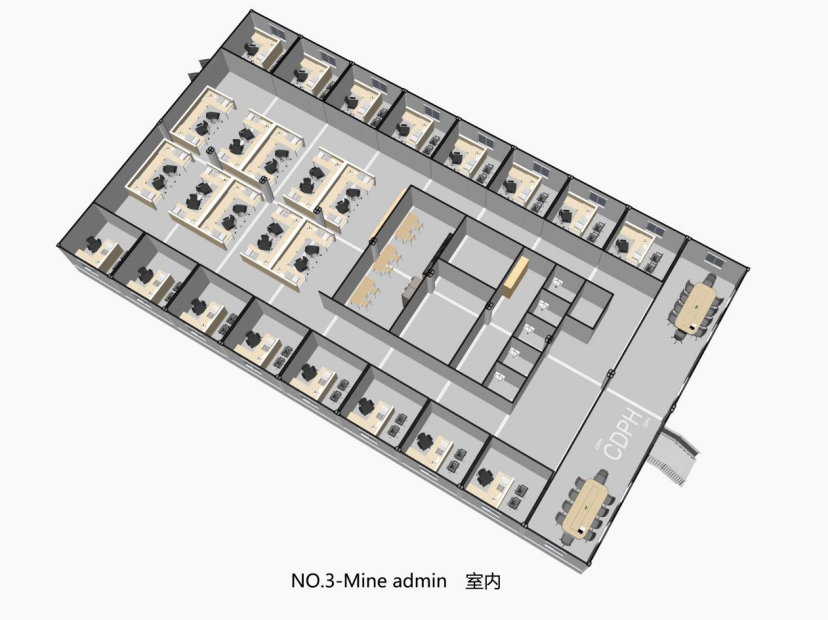

Interior Layout, HVAC, and Aesthetic Branding in Modular Office Design and Construction Using Shipping Containers

When it comes to customizing container offices, we're talking about much more than just looks. These spaces need to work well functionally too, respond appropriately to different climates, and reflect company branding effectively. Interior designs can be really flexible these days. Some areas are set up for team meetings while others have soundproofed private spaces where people can focus without distractions. The buildings still maintain their structural strength despite all this customization. Heating and cooling systems get tailored specifically for whatever weather conditions exist locally. This approach saves money on running costs, sometimes cutting expenses by around 30% when compared to traditional office construction methods. What happens outside matters just as much as inside. Companies often spend extra on special exterior materials and unique interior finishes so their containers don't look generic anymore. Research indicates that thoughtfully designed workspaces actually improve how productive employees feel during their day. Around 15% increase in productivity has been observed in some cases. Container offices aren't merely convenient temporary setups anymore. They represent smart investments for businesses looking to establish presence quickly without breaking the bank.

FAQ

What is a container office?

A container office is a workspace created by converting shipping containers into functional office spaces. They are modular, portable, and customizable.

How fast can container offices be deployed?

Container offices can be deployed in 3–5 months, significantly faster than traditional buildings, which take 9–12 months.

Are container offices cost-effective?

Yes, container offices generally offer a 25% lower capital expenditure, reducing foundation/utility costs and minimizing material waste.

Do container offices meet building codes?

Yes, container offices comply with building codes, including fire suppression, ADA access, and IECC energy efficiency standards.

Can container offices be customized?

Yes, container offices can be highly customized in terms of interior layout, HVAC, and aesthetic branding.