Sustainable Design: Transforming Containers into Eco-Friendly Homes

From Industrial Containers to Residential Innovation: The Reuse Advantage

Taking old containers and turning them into homes helps solve the problem of all these retired metal boxes sitting around unused. When someone converts a standard 40 foot container, they keep about 3,500 kilograms of steel out of landfills. Plus, it saves on the energy costs and materials needed if those same houses were built from scratch. The whole idea of reusing these massive steel boxes actually gives us several important environmental advantages, though we'll need to talk about what exactly those are another time.

- Waste diversion from marine junkyards

- Embodied energy conservation by reusing existing structures

- Reduced mining demand for new construction steel

Tiny homes built from shipping containers are becoming a big part of sustainable living trends these days. The containers themselves are so sturdy they don't need much extra support structure, which means manufacturers aren't pulling down trees for lumber all over again. A recent study from the Construction Waste Recycling Association found something pretty impressive too - when converting containers into homes, builders end up using about 60 percent less brand new material compared to building similar sized houses the conventional way. That makes sense when thinking about all those wasted resources going into regular construction projects.

Carbon and Waste Reduction: Container Construction vs. Traditional Framing

Container tiny homes offer measurable sustainability advantages over conventional building methods. Waste generation is significantly lower: traditional framing produces about 2.2 tons of waste per 200 sq ft unit, whereas container projects generate under 0.8 tons due to precision engineering and modular efficiency.

| Construction Method | CO2 Emissions per Unit | Material Waste Generated | Primary Materials Used |

|---|---|---|---|

| Container Tiny Homes | 3.8 tons | 0.7-0.9 tons | Recycled steel, reclaimed wood |

| Traditional Framing | 6.1 tons | 2.1-2.4 tons | New lumber, concrete, virgin steel |

The carbon footprint gets cut down quite a bit too. When builders use modular fabrication methods, they can reduce on site work by roughly 30 to 40 percent, which means fewer trucks coming and going plus lower overall energy consumption during construction. For tiny homes specifically, new insulation tech has made all the difference. Take those aerogel infused panels for instance. They tackle thermal bridging issues while still fitting into thin walls, something that was pretty much impossible before. Tiny home owners really notice the difference in efficiency. According to various Life Cycle Assessments looking at the whole picture from materials sourcing to eventual demolition, these kinds of improvements lead to about 40 percent less carbon emitted over time when compared with traditional building approaches. Makes sense why more people are making the switch nowadays.

The 200-Sq-Ft Living Standard: Modular Design for Full-Function Homes

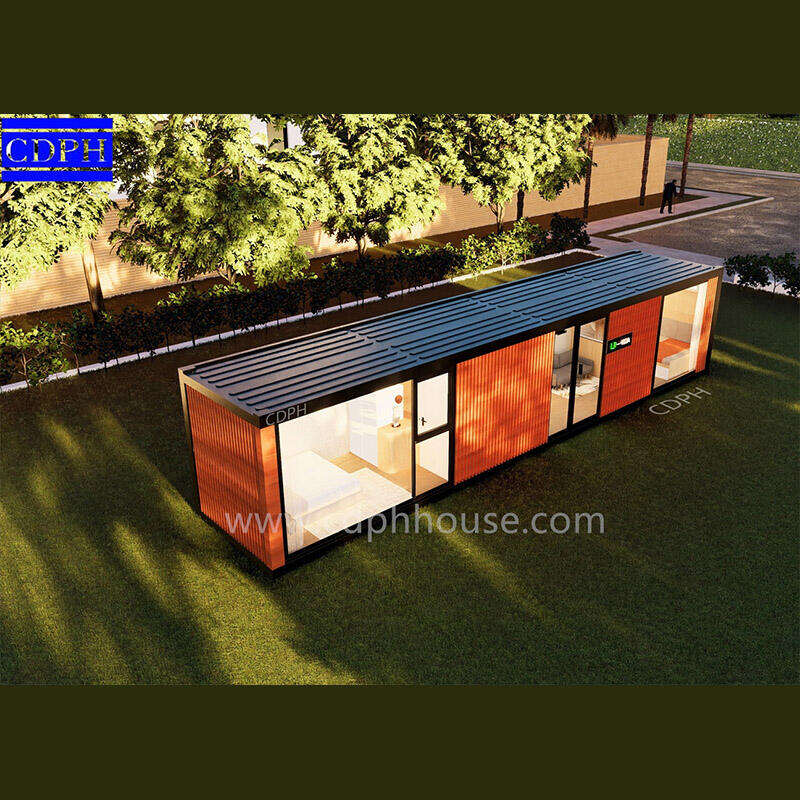

Tiny homes made from shipping containers show just how much can fit into less than 200 square feet when designed properly. Getting down to that 200 sq ft mark works best when there's no extra walking space between rooms because everything flows together so well. Most people go for open floor plans where the kitchen blends right into the living area and bedroom space. Bathrooms get smaller but still work great with all necessary functions packed into one small area. Walls become storage solutions thanks to built-in cabinets everywhere, and things like fold-out desks come in handy for saving space during the day. Containers that are squares or rectangles actually save money on materials since they waste less stuff around the edges. These shapes also cut down on building expenses by roughly 30 percent compared to weird shaped containers. And despite their size, these tiny homes manage to include everything needed for daily living without feeling cramped at all.

Vertical Zoning and Multi-Functional Furniture in Single-Container Layouts

In single-container homes, vertical space becomes a critical design asset, especially with ceiling heights often exceeding 8 feet. Lofted sleeping areas free up ground-level space for daily activities and create distinct functional zones. Furniture is selected for dual-purpose utility:

- Staircases include pull-out drawers and hidden compartments

- Expandable dining tables fold flush against walls when not in use

- Ottoman seating conceals bedding or seasonal storage

Integrated solutions like convertible sofa-beds and sliding room dividers allow dynamic reconfiguration. This layered strategy maintains visual openness while supporting everyday routines, proving that compact container living can be both practical and comfortable.

The Utility Stack: Optimizing Workflow in Compact Container Homes

Container tiny homes rely heavily on what designers call the utility stack concept. Basically, it combines kitchen, bathroom, sleeping area, and storage all in one vertical space. Smart furniture choices really make this work. Take sinks that extend out as extra counter space, or loft beds with hidden drawers underneath. Some folks even install wall mounted tables that fold down during the day for working at, then flip up at night to become dining spots. The appliances tend to be smaller versions of regular ones, tucked neatly inside custom made cabinets. Every square inch gets used somehow, which turns spaces under 200 square feet into surprisingly comfortable living areas where people can move around without feeling cramped. Storage solutions often go where most would never think to look. For instance, there might be cabinets installed beneath staircases or right above door frames, making different parts of the home flow together smoothly instead of feeling separate.

Passive Solar Design, Ventilation, and Thermal Mass Strategies

When building tiny homes from shipping containers, positioning them properly relative to the sun makes a big difference in how much energy they consume. Putting windows on the south side lets plenty of warm winter light inside, but smart builders add roof overhangs and other shade solutions to keep things from getting too hot during summer months. Concrete floors work great as thermal mass storage, soaking up heat during the day then giving it back when nights get chilly. Many container homes also incorporate cross ventilation systems that take advantage of local wind patterns for natural cooling effects. According to some recent studies from the US Department of Energy, this kind of design can cut down on air conditioning usage by around thirty percent compared to regular houses. All these features combined explain why so many people find container homes not just practical but also pretty good for the environment in the long run.

Insulation and Climate Adaptation for Year-Round Comfort

A continuous exterior insulation layer—typically spray foam or rigid panels—forms an airtight thermal envelope around steel container structures, preventing condensation and thermal bridging. Insulation strategies are tailored to regional climates:

- Arctic zones use R-30+ insulation with triple-glazed windows

- Humid climates incorporate vapor barriers and moisture-wicking materials

- Desert regions combine reflective roof coatings with thermal breaks

These climate-specific solutions maintain interior temperatures between 68—78°F with minimal energy input, demonstrating that well-designed container homes outperform traditional buildings in lifecycle energy efficiency.

FAQ

Q: How much steel is saved by converting a shipping container into a home?

A: A standard 40-foot container keeps about 3,500 kilograms of steel from ending up in landfills when converted into a home.

Q: How do container homes reduce construction waste compared to traditional homes?

A: Container projects generate under 0.8 tons of waste per 200 sq ft unit, whereas traditional framing produces about 2.2 tons of waste due to precision engineering and modular efficiency.

Q: What insulation is used for container homes in Arctic zones?

A: Arctic zones use R-30+ insulation with triple-glazed windows to maintain comfort in extreme climates.

Table of Contents

-

Sustainable Design: Transforming Containers into Eco-Friendly Homes

- From Industrial Containers to Residential Innovation: The Reuse Advantage

- Carbon and Waste Reduction: Container Construction vs. Traditional Framing

- The 200-Sq-Ft Living Standard: Modular Design for Full-Function Homes

- Vertical Zoning and Multi-Functional Furniture in Single-Container Layouts

- The Utility Stack: Optimizing Workflow in Compact Container Homes

- Passive Solar Design, Ventilation, and Thermal Mass Strategies

- Insulation and Climate Adaptation for Year-Round Comfort

- FAQ