Understanding Prefab House Kits: Types, Scope, and Core Distinctions

Modular, panelized, and hybrid prefab house kits explained

There are basically three main types of prefab house kits out there, each built differently. Modular homes come almost ready to go, usually about 80 to 90 percent finished at the factory. These big chunks get lifted right onto foundations and put together pretty fast. Then there's panelized systems where companies send flat packed walls and roofs already insulated and wired, sometimes even with windows installed. People still need to frame them on site though. Hybrid kits mix things up combining modular parts like kitchens and bathrooms with panelized exteriors or extra rooms. This gives builders a good middle ground between getting things done quickly and having some custom touches. Compared to regular stick built houses, these prefab options avoid those annoying weather delays and generate around 30% less waste because everything gets made so precisely in factories according to the National Association of Home Builders report from 2023 on prefab construction.

How turnkey prefab homes differ in delivery, responsibility, and completion level

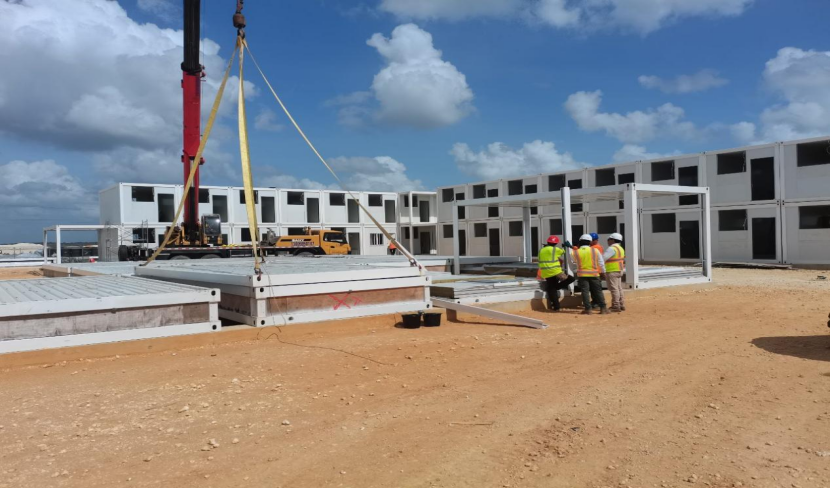

With turnkey prefab homes, the entire project runs from start to finish under one roof literally. Unlike those DIY kits that just throw together some materials and instructions, these complete packages handle everything at once. Think about it: someone else takes care of getting the land ready, laying down foundations, placing modules with cranes, dealing with permits, and running all the final checks. Contractors become responsible for making sure everything meets codes, managing other workers, and connecting all systems properly. When the job is done, homeowners walk into spaces that are completely furnished inside already. Flooring? Check. Cabinets? Installed. Lights, heating systems, pipes, outlets – all set up and working out of the box. Sure, people pay around 20 to 35 percent extra compared to building themselves, but nobody has to worry about scheduling meetings, checking technical details, or taking legal risks anymore. Makes sense why folks choose this option when facing tricky construction sites or tight deadlines.

DIY Prefab House Kits: Realistic Costs, Skills, and Timelines

Breaking down true cost: savings on materials vs labor, tools, and delays

The material savings in prefab house kits can be pretty impressive too around $30 to $150 per square foot for those core parts but honestly these numbers don't always mean cheaper overall costs. Let's talk about site prep first because that alone will set homeowners back between twenty and fifty grand just for digging, leveling ground, and getting proper drainage sorted. Then there are foundations which vary wildly from six thousand up to thirty thousand bucks depending on what kind of foundation they need and how good the soil is. Utility connections water lines, sewage systems, electricity, maybe a septic tank those typically cost somewhere between six thousand five hundred and thirty thousand dollars. And we haven't even mentioned all the other stuff nobody thinks about when they start building like special tools needed for assembly running anywhere from three to fifteen thousand dollars, permits and engineering reports costing another one thousand five hundred to seven thousand five hundred, plus finishing touches inside at roughly thirty to sixty dollars per square foot. First time builders should also know something important most end up spending 15 to 25 percent more time on their projects than planned because of bad weather, mistakes made during construction, or having to fix things twice. All this extra time eats away at any labor savings and pushes up those hidden costs such as insurance premiums and loan interest rates. So what looks like a great deal initially might actually turn out to be about the same price or even more expensive if people don't plan everything out realistically from day one.

Time commitment by builder profile: skilled contractor vs first-time DIYer

An experienced contractor who knows their way around trade networks and has solid project management skills can wrap up a DIY prefab house within about 3 to 6 months total. Site preparation and getting the foundation right usually takes around 1 or 2 weeks. Putting together the actual structure might only take 3 to 5 days depending on conditions. But then comes the real grind: mechanical systems, insulation, drywall, and all those finishing touches generally eat up anywhere from 8 to 12 weeks. For folks tackling this as their first DIY project, expect at least double that timeframe. Reading blueprints correctly, making adjustments when things aren't aligned properly, and sealing those joints against weather all tend to eat away at schedule buffers week after week instead of just a few extra hours here and there. Installing mechanical systems like HVAC, plumbing, and electrical requires specific expertise. Get something wrong and it could mean failing inspections or having to spend big bucks fixing mistakes later. Contractors working without proper coordination will simply bill more for patchwork jobs (we're talking $50 to $200 per hour sometimes). This stretches out both how long things take and what they cost. The bottom line? Good project management matters far more than just being able to swing a hammer effectively.

Turnkey Prefab House Kits: When Convenience Justifies the Premium

Value analysis: 20–35% premium for integrated permitting, site prep, and warranty

Turnkey prefab homes typically cost 20 to 35 percent more than other options, but this extra expense actually represents added value rather than just padding the bottom line. What these providers handle includes all those frustrating, risky steps that usually trip up do-it-yourselfers: getting zoning approvals sorted out, running soil tests, designing foundations that meet engineering standards, and coordinating utilities connections. These are the very things that can hold up home building projects for months at a time. With their existing network of contractors, turnkey companies cut out multiple layers of bidding and create smooth transitions from digging holes in the ground to laying down foundations and finally placing modules. And here's what really matters: most turnkey deals come with solid structural warranties lasting around ten to fifteen years, covering everything from materials to workmanship. This means the homeowner isn't left holding the bag if something goes wrong down the road. For people who don't have much spare time, own property far from town, or face complicated regulations, paying that premium essentially trades unpredictable delays and financial surprises for clear timelines, steady payments, and actual accountability when problems arise.

Risk mitigation: how turnkey models reduce coordination gaps and liability exposure

Prefab homes built on a turnkey basis solve a big problem in traditional construction by putting everything under one roof literally and figuratively. When companies handle all aspects from blueprint to final installation, they take full charge of electricians, plumbers, and foundation crews too. This makes sure everyone follows city regulations and meets quality standards that might otherwise get overlooked. Homeowners don't have to worry about those little things that go wrong in self-built projects like walls that don't line up properly or pipes that are too small for the job. These mistakes often lead to failed inspections or problems showing up months later. What's really nice is how warranties work here. If there are issues down the road with things like settling foundations or drafts coming through poorly sealed areas, it's the builder who fixes them at no extra cost to the owner. The whole process becomes much simpler when designers, manufacturers, and installers work together from start to finish rather than passing responsibilities back and forth like hot potatoes.

FAQ

What are the main types of prefab houses?

The main types of prefab houses include modular homes, panelized systems, and hybrid kits. Each type involves different methods of construction and levels of site assembly.

How do turnkey prefab homes differ from DIY kits?

Turnkey prefab homes come as complete packages where a company manages the entire building process from land preparation to final inspections. DIY kits involve the homeowner taking on much of the coordination and construction themselves.

Are prefab house kits cost-effective?

While prefab house kits can offer material savings, the overall cost-effectiveness depends on factors like site preparation, foundation requirements, utility connections, and the homeowner's management skills.

How much time does it take to build a prefab home?

A skilled contractor can typically complete a DIY prefab house in 3 to 6 months, while first-time DIYers might take double the time due to learning curves and unexpected challenges.