Cost Comparison: Building vs Buying a Container Home

Initial Cost of Building a Container Home vs Buying Prefab

Building costs for container homes vary quite a bit depending on how much work someone wants to do themselves. A simple DIY project might start around ten grand, but folks who want something nicer usually spend closer to fifty thousand dollars on their own custom builds. Prefab models tend to land somewhere between fifty and seventy thousand bucks. The reason behind this price gap? Containers themselves are basically ready made shells, so there's less need for materials and fewer workers required for construction. Still worth noting though, those starting prices don't include things most people actually need like proper insulation, running water connections, electrical systems, or even basic wall finishes inside. Once all those extras get added in, the total amount needed jumps way beyond what many initially expect for either building method.

Hidden Expenses in DIY Container Home Construction

DIY builders often face unexpected costs such as permits ($1,000–$5,000), foundation work ($5,000–$15,000), and specialized labor for welding or structural modifications. Insulation and weatherproofing—critical for livability—add $3,000–$8,000, while plumbing and electrical installations can reach $10,000–$20,000 depending on site conditions. These hidden expenses frequently push total project costs 30–50% above initial estimates.

Long-Term Savings and Financial Trade-Offs

DIY construction might take more work at first but pays off big time over the years with smaller monthly payments and cheaper insurance bills. Container homes typically save homeowners between 20 to 40 percent compared to regular houses built by professionals, especially when folks do most of the work themselves. According to last year's Sustainable Housing Report, people who build their own homes end up keeping more money in their pockets as equity grows, plus they get to spend what they want when they want during construction. Customizing things as they go along gives builders real control over their finances instead of handing everything over to contractors.

Case Study: $30,000 Custom Build vs $50,000 Purchased Model

Looking at two different 40 foot container homes shows some interesting money matters. One person built theirs from scratch spending around 30 grand total, including nice finishes inside. But they put in about 800 hours themselves working on it week after week. The other option was buying a prebuilt container home which came out to 50 thousand dollars but included all the professional work needed to move right in. Someone who went the DIY route actually ended up saving roughly 35k over five years just on their mortgage payments and interest costs. So even though building takes a lot of time upfront, those extra hours really pay off down the road financially speaking.

Design Flexibility and Customization: Build vs Buy

Full Design Control in Build a Container Home Projects

Creating a container home from the ground up gives designers way more creative freedom than those factory made prefabs ever could. Starting fresh means having total say over everything from how the rooms are arranged to what kind of materials get used on walls and floors. The whole process allows for all sorts of special touches too, whether it's adapting to weird terrain or changing plans halfway through because something just doesn't feel right anymore. Sure, making big adjustments later can push back completion dates and eat into savings, but that extra flexibility is worth it when building something truly custom that no cookie cutter model could ever match.

Limitations in Prefab Container Home Purchase Options

Container homes built off the production line tend to have pretty limited design possibilities because manufacturers stick to standard processes for efficiency. The majority of builders just hand out set floor plans with hardly any room for changes since they need to keep things running smoothly and control costs. A few companies will let buyers tweak some interior details or select different finishes, but really nothing much can be done about the basic size or how the structure is put together. Looking at what's happening in the market right now, these small customizations typically push prices up around 15 to 25 percent above the standard model cost, even though everything still has to fit into those same old templates that manufacturers have been using for years.

Structural and Space Limitations in Container Modifications

Container homes, whether custom built or prefabricated, come with their own set of space limitations and structural headaches. Most standard shipping containers measure just 8 feet across, so folks wanting decent sized living areas usually need to connect several units together. When it comes to making doorways and windows in these metal boxes, proper engineering becomes absolutely critical. Steel walls can't just be hacked away without weakening the whole structure. And let's not forget about those wavy steel surfaces either. Insulating them properly and getting drywall to stick straight is no small task. These problems pop up no matter if someone builds from scratch or purchases an already assembled container home.

Time, Skill, and Effort: DIY Construction Challenges

Time Investment for Building a Container Home from Scratch

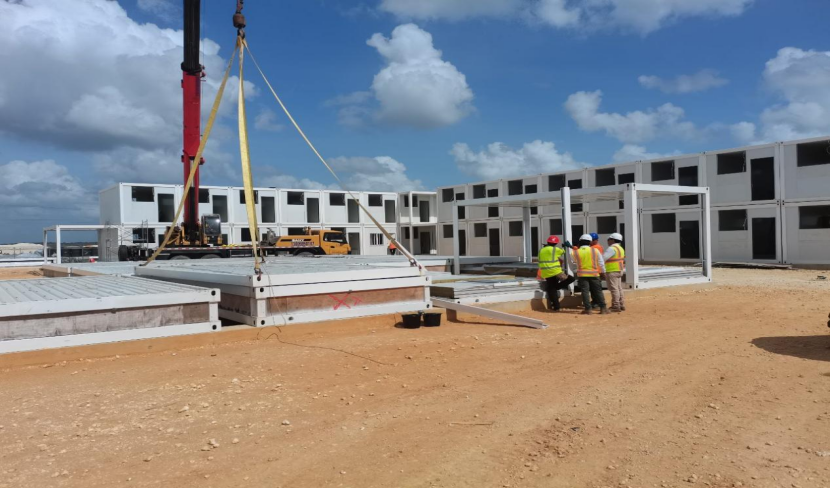

Most people who build container homes themselves find they spend anywhere between six to twelve months getting everything done, while professional builders usually finish within two to four months. The process covers all sorts of stuff like figuring out designs, getting those pesky permits approved, hunting down materials, and actually doing the construction work on site. DIY projects face challenges that factory made homes don't have to worry about much at all. Rainy days can really slow things down, folks often need time to learn how to do certain tasks properly, and mistakes happen that require going back and fixing them later. Looking at numbers from Westshore Home in 2024 shows something interesting too: around eight out of ten homeowners end up taking 30 to 50 percent longer than originally planned. That makes sense when thinking about all the unexpected hurdles that come along during such projects.

Skill Requirements and Safety Concerns in DIY Builds

Creating a container home means having some real skills under your belt when it comes to welding, understanding how structures hold together, dealing with electricity, and knowing what works for insulation. Painting walls or putting up shelves? That's something most people can handle without breaking a sweat. But when things get to actually changing the structure itself or running utilities through those thick metal walls, that's where professionals really shine. Let's face it, lifting around those massive steel containers isn't just tough work—it's dangerous work. And messing with power lines? Not something to take lightly. Most building codes and safety manuals will tell anyone thinking about this project that if they're going to mess with anything that supports the whole house, run electricity throughout, or install heating and cooling systems, they need someone with proper credentials doing the job. Safety first, right?

Speed Advantages of Buying a Prefabricated Container Home

Buying a prefabricated container home saves a ton of time compared to traditional builds. Most people get their containers delivered within around 8 to maybe 14 weeks once they place an order. These ready-made packages cut out all the hassle of designing from scratch, dealing with permits, and waiting for construction crews to show up on site. The factory setting means everything gets built with much greater accuracy since workers have access to special equipment and know exactly what they're doing. Because everything happens offsite, folks can move into their new space way faster than if they tried to build it themselves. No need to figure out how to mix concrete or deal with unexpected weather delays. That's why so many busy professionals and families looking to settle down quickly are turning to these prefab options instead of going through the whole traditional building process.

Durability, Maintenance, and Lifespan of Container Homes

Material Strength and Structural Integrity of Shipping Containers

Most shipping containers are built using corten steel because they need to survive rough ocean trips and stack safely on top of each other, sometimes nine layers deep. Because of how strong these boxes are, many people have started converting them into homes. But there's a catch when making changes like cutting out doors or installing windows. The container needs extra support at those spots to keep it structurally sound. If someone works carefully through the modification process, the container still holds up pretty well against weather and other outside forces over time.

Corrosion, Weathering, and Ongoing Maintenance Challenges

Steel containers may be strong but they still get corroded pretty easily, especially when placed near the coast or in areas where humidity is high. To stop this rust problem, regular checks and applying protective layers becomes really important. Most people find that using zinc primer first works best, then adding some kind of moisture barrier helps too. Good airflow around the container makes a big difference as well. There are other issues worth mentioning though. Thermal expansion happens when temperatures change a lot, and condensation builds up inside if there's not enough drainage. The paint on the outside gets damaged by sunlight over time too. All these problems mean ongoing maintenance isn't optional if someone wants their steel containers to last for years instead of just months.

Expected Lifespan: 25+ Years with Proper Insulation and Coating

Container homes typically stand for around 25 to 50 years if looked after correctly. How long they actually last really comes down to three main factors: how good the insulation is, whether the coatings get regular attention, and what kind of weather conditions they face day after day. Most builders agree that decent insulation does double duty by saving on energy bills while preventing moisture buildup inside walls that leads to rust problems over time. Regular maintenance matters too. A fresh coat of paint every few years, treating any spots where rust starts to form, and checking for structural issues can push those 25 year numbers much further out. For anyone thinking about going the container home route, these steel boxes prove pretty tough when someone actually takes the time to maintain them properly.

Environmental Impact and Legal Considerations

Sustainability of Recycling Steel Containers for Housing

Taking old shipping containers and turning them into living spaces has become quite popular lately as a way to keep steel out of landfills while cutting down on the need for brand new building stuff. Think about this number: recycling just one container saves roughly 8,000 kilowatt hours worth of energy versus making fresh steel from scratch. Container homes actually beat traditional houses in several green categories too. The real advantage comes when folks go the extra mile with things like proper insulation that doesn't harm the planet, grabbing materials from nearby sources instead of shipping them halfway across the country, and hooking up solar panels or other clean power options whenever possible.

Carbon Footprint: Built vs Bought Container Homes

How much carbon a container home produces really depends on how it gets built and where materials come from. When people build these things themselves, they tend to make several trips back and forth to different suppliers, which wastes fuel. Plus, leftover materials just pile up in garages or get thrown away instead of being used properly. On the other hand, prefabricated units do have advantages since factories can streamline production processes. But there's a catch many folks overlook transport costs skyrocket when shipping containers thousands of miles across country or even internationally. According to research published last year by sustainability experts, homes constructed locally typically emit around 15 to 20 percent less carbon compared to those brought in from far away. Of course this number fluctuates quite a bit depending on exactly how far everything travels and whether companies manage their supply chains efficiently enough to cut down waste along the way.

Zoning Laws, Permits, and Legal Hurdles by Region

Container homes run into all sorts of roadblocks when it comes to zoning laws and building codes since these regulations change so much from one place to another. Most towns have rules about what kind of materials can be used, how big the space needs to be, and even what the house looks like outside, which makes getting permission tricky. According to some recent numbers from early 2024 looking at permits across different regions, around a third of all container home proposals either get delayed or need significant changes before they'll pass inspection. Anyone thinking about building this way should really spend time researching exactly what their local government requires regarding land usage and compliance issues well before buying any property or shipping containers. The countryside usually has fewer restrictions compared to cities where authorities often stick closely to traditional construction methods and may not look kindly on anything too unconventional.

FAQ

What are the initial costs of building versus buying a container home?

The initial cost of building a container home starts at around $10,000 for DIY projects and can go up to $50,000 for custom builds, whereas prefab models range between $50,000 and $70,000.

What are some hidden expenses in DIY container home constructions?

DIY builders may face unexpected costs such as permits ($1,000–$5,000), foundation work ($5,000–$15,000), insulation and weatherproofing ($3,000–$8,000), and plumbing and electrical installations ($10,000–$20,000).

How do container homes offer long-term savings?

Container homes can save owners between 20 to 40 percent on costs compared to traditional homes, mainly due to smaller monthly payments, cheaper insurance, and increased financial control.

What is the time investment for building a container home?

Building a container home from scratch can take between six to twelve months, while professional builders usually complete the project in two to four months.

What are the environmental benefits of container homes?

Recycling steel shipping containers for housing can reduce waste, conserve energy, and minimize the need for new materials, with a single container saving roughly 8,000 kWh of energy.

What are some legal considerations when building a container home?

Zoning laws and permits vary by region and can be challenging, with about a third of proposals potentially facing delays or necessary changes to meet local regulations.

Table of Contents

- Cost Comparison: Building vs Buying a Container Home

- Design Flexibility and Customization: Build vs Buy

- Time, Skill, and Effort: DIY Construction Challenges

- Durability, Maintenance, and Lifespan of Container Homes

- Environmental Impact and Legal Considerations

-

FAQ

- What are the initial costs of building versus buying a container home?

- What are some hidden expenses in DIY container home constructions?

- How do container homes offer long-term savings?

- What is the time investment for building a container home?

- What are the environmental benefits of container homes?

- What are some legal considerations when building a container home?