Why Businesses Are Turning to Modular Office Buildings

Growing Demand for Agile, Scalable Workspaces in Modern Organizations

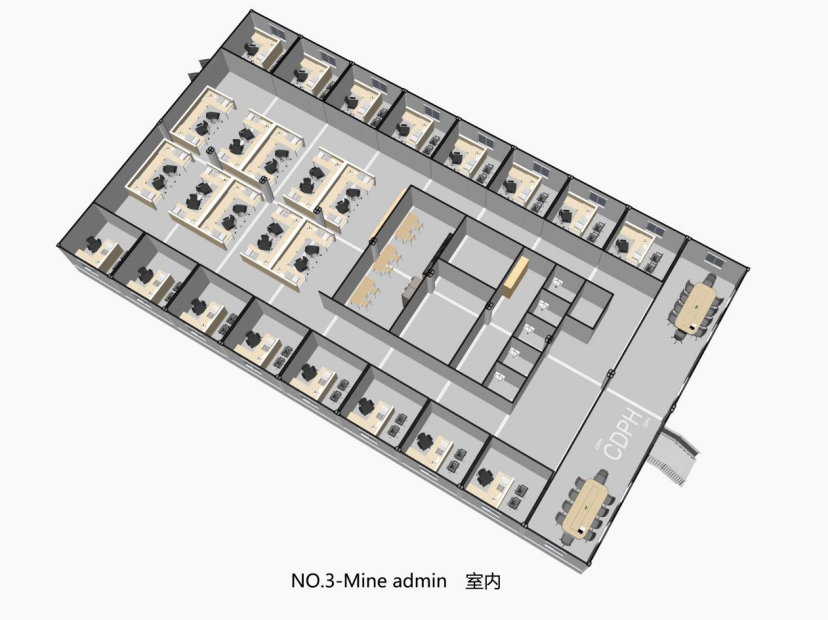

Businesses today are really starting to focus on work environments that can handle changing numbers of staff, temporary project groups, and shifting day-to-day operations. That's where modular office buildings come in handy. These prefabs get put together much quicker than regular construction takes, sometimes cutting down deployment time by around 30 to 50 percent according to MicroflexSpace research from last year. What makes these spaces so valuable is they let companies grow their office footprint bit by bit without spending tons of money upfront on permanent property. Take manufacturing plants for instance. Many of them set up these modular offices right inside their warehouses. This creates mixed-use areas where managers can have meetings while engineers work nearby. As production schedules change throughout the year, these flexible setups make it easy to rearrange things without tearing everything apart.

Aligning Real Estate Strategy with Hybrid and Remote Work Models

According to Forbes from last year, around 74% of American companies have gone hybrid with their work arrangements. This means offices need to be designed differently now, finding ways to bring people together face to face but still allow for remote workers too. Modular setups are becoming popular because they let companies change how their spaces look over time. Think movable meeting rooms, flexible seating areas where anyone can drop in, even small satellite locations close to where many employees live. These kinds of adaptable spaces help cut down on those expensive long term leases while keeping everyone connected within the company culture. The JLL research group did a study recently showing something interesting about this trend. Companies that switched to these modular office concepts actually used their available space about 18 percent better than those stuck with old fashioned fixed layouts.

Case Study: Tech Startup Scales Operations Using Modular Office Building Solutions

A fast-growing SaaS company based in the heart of Silicon Valley was running out of space when they tried to expand their offices last year. The usual building permits took forever to process through local zoning regulations. So instead of waiting months for construction crews, they went with modular office solutions inside their current warehouse facility. Within just eight weeks, these prefabricated workspaces gave them an extra 5,000 square feet of usable area, which beat traditional building timelines by about half. What really stood out though was how flexible everything remained. Every three months, the engineering team could rearrange those lab spaces and meeting areas depending on what projects were hot at the moment. According to industry research from Ponemon Institute back in 2023, this approach saved them around $740,000 compared to moving somewhere else entirely. Plus it kept everyone working together face-to-face during those intense product development phases when collaboration matters most.

Speed of Construction: How Modular Office Buildings Cut Project Timelines by 50%

Off-Site Fabrication Minimizes Delays and Weather Risks

Office buildings built in modular fashion typically finish construction 30 to 50 percent quicker compared to regular building methods since around 60 to 80 percent gets done inside factories where conditions are stable. Foundations get laid out at the actual construction site while the building parts themselves are being made elsewhere at the same time. This kind of overlapping process means no delays caused by rain or snow stopping work. Projects tend to wrap up anywhere from four months to half a year sooner than expected. Most of these modules have steel frames designed so they snap together pretty much exactly when brought to the site for final installation.

Case Study: Retail Chain Deploys Prefab Office Units in Just 6 Weeks

A major national retailer recently set up a modular office space covering around 12,000 square feet to handle their growing regional needs. They built 48 prefabricated office modules in just four weeks at the factory while simultaneously getting the site ready for foundations during those last two weeks. Everything was installed and running smoothly within six weeks total. The quick turnaround let them hit their third quarter growth goals without having to rent extra temporary offices somewhere else. Modular building really works when companies need something fast but still professional looking, which makes sense given how competitive retail markets can get these days.

Fast Office Construction Meets Urban Development Demands

Cities prioritizing infill development increasingly adopt modular office buildings to reduce construction-related traffic disruptions by 70%. A 2023 urban planning study found modular projects complete permit-to-occupancy phases 58% faster than traditional builds, accelerating activation of underutilized commercial parcels. This efficiency supports municipal goals for economic growth while minimizing community disruption.

Cost Efficiency and Budget Predictability in Modular Office Projects

Up to 20% Reduction in Total Project Costs Explained

When it comes to building offices, modular structures actually cost about 15 to 20 percent less over their entire lifespan compared to regular construction methods. This savings happens because materials get used more efficiently and the whole process takes significantly less time from start to finish. The factory controlled environment means there's far less need for fixing mistakes later on something that usually eats up around 6 to 8 percent of what companies spend traditionally. Plus workers don't have to wait around as much since different parts of the project can happen at once, cutting down labor costs somewhere between 30 and 40 percent. A recent look at how efficient construction is these days showed that modular buildings end up wasting roughly 18 percent less steel and about 22 percent less concrete too. That's mostly because factories can make super accurate digital cutting lists that just aren't possible when everything gets built on site.

Factory-Controlled Processes Reduce Waste and Overtime Expenses

Climate-controlled manufacturing avoids weather delays affecting 74% of traditional projects. Inventory management systems cut material overordering by 19%, and assembly-line workflows reduce overtime premiums by 35%. Energy consumption during production is also 28% lower than conventional methods, thanks to fixed equipment layouts and bulk material handling.

Overcoming Upfront Cost Perceptions with Long-Term Value

While the initial price tag tends to be about the same as regular construction methods, modular buildings actually save money because they finish construction around 50% quicker. This means businesses can start making money anywhere from 7 to 11 months sooner than usual. Plus, these buildings can be moved later on, so companies keep roughly 80 to 90 percent of what they paid originally when they need to relocate. Traditional office spaces lose value every year at a rate of 4 to 6 percent though. And let's not forget about energy savings either. The modular ones cut down on heating and cooling expenses too, saving somewhere between $2.50 and $3.75 for each square foot yearly compared with standard buildings that just meet basic building codes.

Scalability and Flexibility: Adapting Modular Workspaces to Business Needs

Modular office buildings deliver transformative adaptability for businesses facing fluctuating space requirements. Unlike traditional construction, these solutions enable organizations to scale workspaces up, down, or laterally with minimal operational disruption.

Reconfigurable Designs Support Evolving Team Structures

Flexible walls and modular furniture setups let office spaces change shape when team sizes fluctuate or company direction shifts. According to recent research from 2023, about three out of four hybrid workplaces now rely on these adaptable elements to transform wide open spaces into meeting spots or quiet corners for focused work in just a few hours time. No more tearing down walls or running new cables through ceilings. For companies trying to keep their physical environment matching what matters most each quarter instead of being locked into long term lease agreements, this kind of flexibility makes all the difference. Many small business owners I've spoken to recently mention this as one of their top considerations when looking at new office locations.

Case Study: Manufacturing Plant Expands with Portable Modular Offices

An auto parts manufacturer in the Midwest recently set up nine portable modular offices next to their main production area. These structures got engineering staff and quality control teams settled in just over six weeks flat. Normally, building something similar would take around a year through traditional methods, but this approach let them get a new $22 million production line running months ahead of schedule. What's interesting is when business picked up and they needed more space, these modular units simply moved as one piece to another part of the campus. The whole operation took less time than most people spend planning their annual budgets, showing how flexible these temporary solutions can be for growing manufacturing operations.

Temporary Office Space for Seasonal or Transitional Business Phases

Businesses across different sectors are turning to modular office rentals these days when they need temporary workspace solutions. Think tax accountants during busy season, farm collectives managing harvest periods, or retailers dealing with Christmas rush inventory problems. The savings here are pretty impressive too many companies report cutting their expenses down between 60 to almost 85 percent compared to traditional long term leases. Plus, these portable offices come equipped with all the necessary safety features and internet access that employees actually need to get work done properly. What's really convenient is how fast everything gets set up once the ground is ready usually around two weeks max. And best part? When the job is finished, the whole setup just packs up and leaves right on schedule with no leftover mess or commitments hanging around.

Sustainability and Operational Benefits of Modular Office Buildings

Lower Carbon Footprint Through Efficient Manufacturing and Assembly

When it comes to reducing construction emissions, modular office buildings cut down on carbon output by somewhere between 30 to 50 percent compared with old school building techniques. The reason? These structures get built in factories first where conditions are controlled rather than on site. And let's talk about waste reduction for a moment. According to data from the Modular Building Institute back in 2022, these prefabricated units generate around 90% less construction debris because everything gets measured so precisely before assembly begins. Plus, since most designs follow standard specifications, they tend to consume energy more efficiently during operation. Many manufacturers also incorporate recyclable steel frames alongside panels made from low volatile organic compounds (VOCs) which means these buildings leave behind far smaller ecological footprints over time. This approach actually aligns pretty well with what many call the circular economy model where resources stay in use longer and eventually get recycled rather than discarded.

LEED-Certified Modular Offices and ESG-Driven Adoption Trends

More than two thirds of Fortune 500 firms have started focusing on LEED certified buildings as part of their environmental, social, and governance commitments. The modular office trend really helps here since many come equipped with solar ready roofing options, ventilation systems that recover heat energy, and intelligent heating cooling systems which cut down on carbon output during operations. We're even seeing pop up offices incorporate nature inspired design elements along with rainwater collection systems these days. Tenants want green spaces and investors are watching closely, so companies need to keep up with what's expected in today's market for sustainable workplaces.

Minimal Disruption Installation and Relocation Capabilities

Traditional office construction takes months before anyone can actually start working there, while modular buildings get up and running within just a few weeks. According to some recent research from the construction industry back in 2023, these modular setups create around 80-odd percent fewer problems with local traffic compared to standard methods because they come together so much quicker. What's really handy is that these modules don't get damaged when taken apart, so companies can literally pack them up and move them somewhere else whenever needed. This makes perfect sense for businesses trying out different locations or dealing with those seasonal ups and downs in staff numbers without having to tear down entire offices every time.

FAQs About Modular Office Buildings

What are the main benefits of modular office buildings?

Modular office buildings offer speedier construction, cost savings, flexibility in design, and sustainability benefits. They can be assembled quickly, adjusted easily for changing needs, and relocated with minimal disruption.

How do modular offices support hybrid work models?

Modular offices are adaptable and can be reconfigured to support both in-person and remote work arrangements, aligning with modern hybrid work models that many companies are adopting.

What is the cost advantage of modular office buildings?

Modular office buildings generally cost 15-20% less over their lifespan due to efficient use of materials, reduced labor costs, and quicker completion times allowing for earlier revenue generation.

Are modular offices a sustainable option for businesses?

Yes, modular office buildings reduce carbon emissions by up to 50% compared to traditional structures. They use efficient manufacturing techniques, generate less waste, and often incorporate recyclable materials and eco-friendly features.

Table of Contents

- Why Businesses Are Turning to Modular Office Buildings

- Speed of Construction: How Modular Office Buildings Cut Project Timelines by 50%

- Cost Efficiency and Budget Predictability in Modular Office Projects

- Scalability and Flexibility: Adapting Modular Workspaces to Business Needs

- Sustainability and Operational Benefits of Modular Office Buildings

- FAQs About Modular Office Buildings